At GoJute we work with a single dedicated factory which ensures jute transparency, no surprises and complete control of production.

All stages of the production process are audited, from sourcing the raw materials, right through to the final production of our products. We have a responsibility to our customers, but we have a larger responsibility to our workers. Ensuring that they are paid a fair wage and work in the best conditions possible is very important to us.

1. Jute seeds are planted in farmland in South East Asia

2. Jute plants are harvested, soaked and dried for processing

3. The ‘golden fibre’ of jute is carefully rolled and stored

4. The experts in the production facility work the fibres into twine

5. The fine jute twine is wound onto a spool ready for weaving

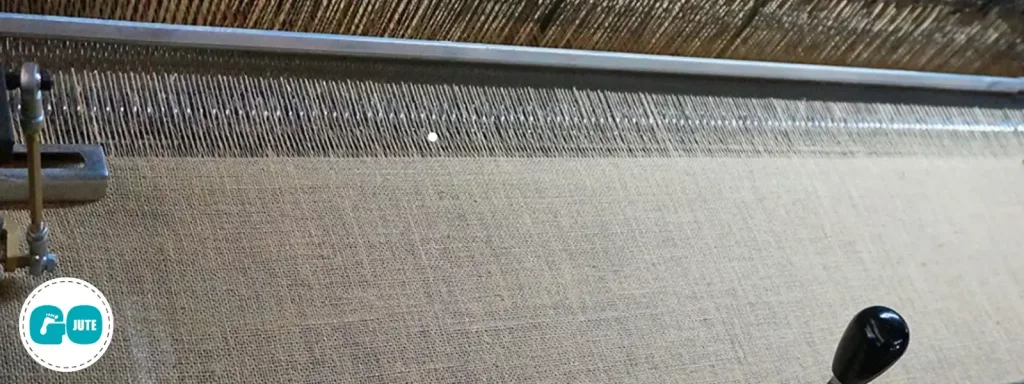

6. The fine threads are interlaced at right angles to create sheets of jute fabric

7. The jute fabric can be dyed at the facility or left natural in colour

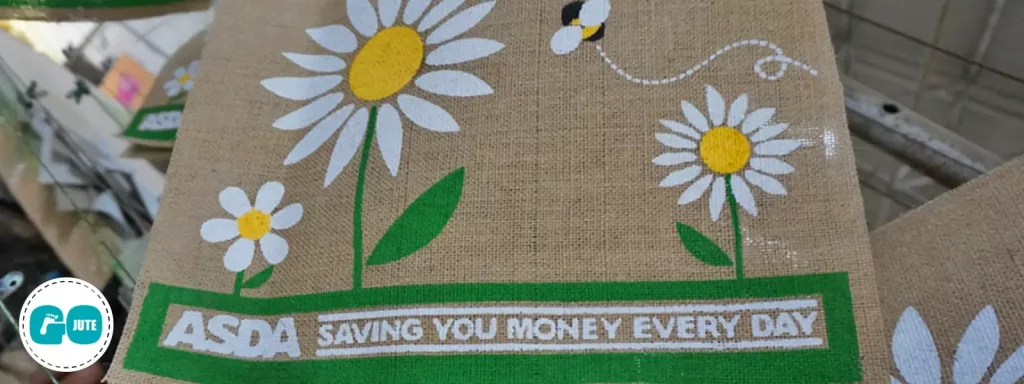

8. Expert seamstresses work the fabric through the sewing machines to create bags of all shapes and sizes

9. Finished bags are securely packed and shipped to the UK

10. Jute bags are transported from the ports to GoJute’s UK print facility

11. Finished bags are unpacked and professionally screen-printed in our UK facility

12. Freshly printed bags are quality checked before being packed and dispatched to clients

As part of our transparent approach, we welcome visits to our production facility from our clients.

Whatever you need for your marketing plan, event or campaign, we can help. Get in touch to speak all things bags with our helpful team or click one of the products below for a closer look.