Screen Printing

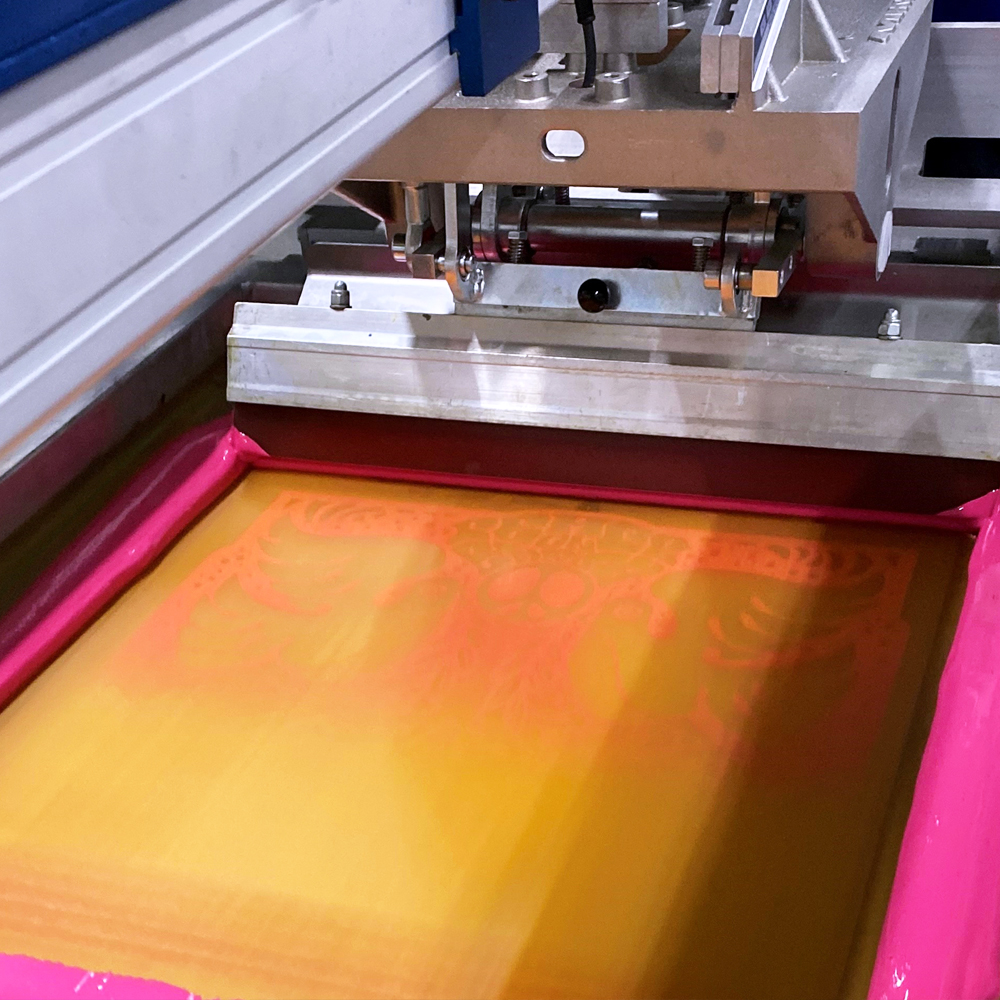

The fifth stage of the manufacturing process is where we print your bespoke artwork onto your bags

Screen printing onto jute bag panels is a process that requires meticulous attention to detail and considerable skill. There are several steps to the process in order to achieve a high-quality and accurate design on the fabric, which by its nature is not the easiest canvas to print onto.

"The use of water-based inks aligns with our sustainable practices"

The first step in screen printing is creating a screen that mimics the desired artwork in its various coloured layers. Multiple screens are used to create multi-coloured artwork. These screens are then placed over the jute fabric panel, and a water-based ink is applied onto the screen. A squeegee is used to push the ink through the mesh onto the jute, transferring the design onto the fabric. Each fabric panel has to dry before the process can be repeated for each colour in the design. An incredible amount of precision is required to aligning all the layers correctly to produce a crisp and vibrant print.

After the printing is complete, the jute panels are dried thoroughly before moving on to the next step, which involves stitching them together to form the final jute bag.

GoJute use OKEO-TEX approved, water-based inks in the screen printing process because they are an environmentally friendly choice. OKEO-TEX is a certification system that ensures textiles and dyes used in the manufacturing process meet stringent environmental and human safety standards. Water-based inks are preferred over solvent-based alternatives because they contain fewer volatile organic compounds (VOCs), reducing air pollution and minimising harm to human health. Furthermore, water-based inks are composed primarily of water, making them more biodegradable and less harmful to the environment compared to traditional solvent-based inks. The use of water-based inks aligns with our sustainable practices, as they have lower environmental impact, produce less waste, and contribute to the overall reduction of harmful chemicals in the production process.

See the jute bag manufacturing process as a whole, or use the button below to read more about the next stage of the process.