Jute Bag Manufacturing Process

The jute bag manufacturing process explained, from farm to arm, illustrating why jute is a fantastic and highly sustainable fabric for bags

Our bags begin life in India as a fast-growing, sustainable plant called jute.

Once harvested the jute is soaked and the fibres separated in a process known as retting. Finally, the jute strips are air-dried.

The strips of jute fibre are loaded onto lorries by the local farmers, where they are transported to the mill to be processed.

The fibres go through many processes such as selection, softening, carding, spinning and weaving. Then the jute fabric can be dyed to any colour.

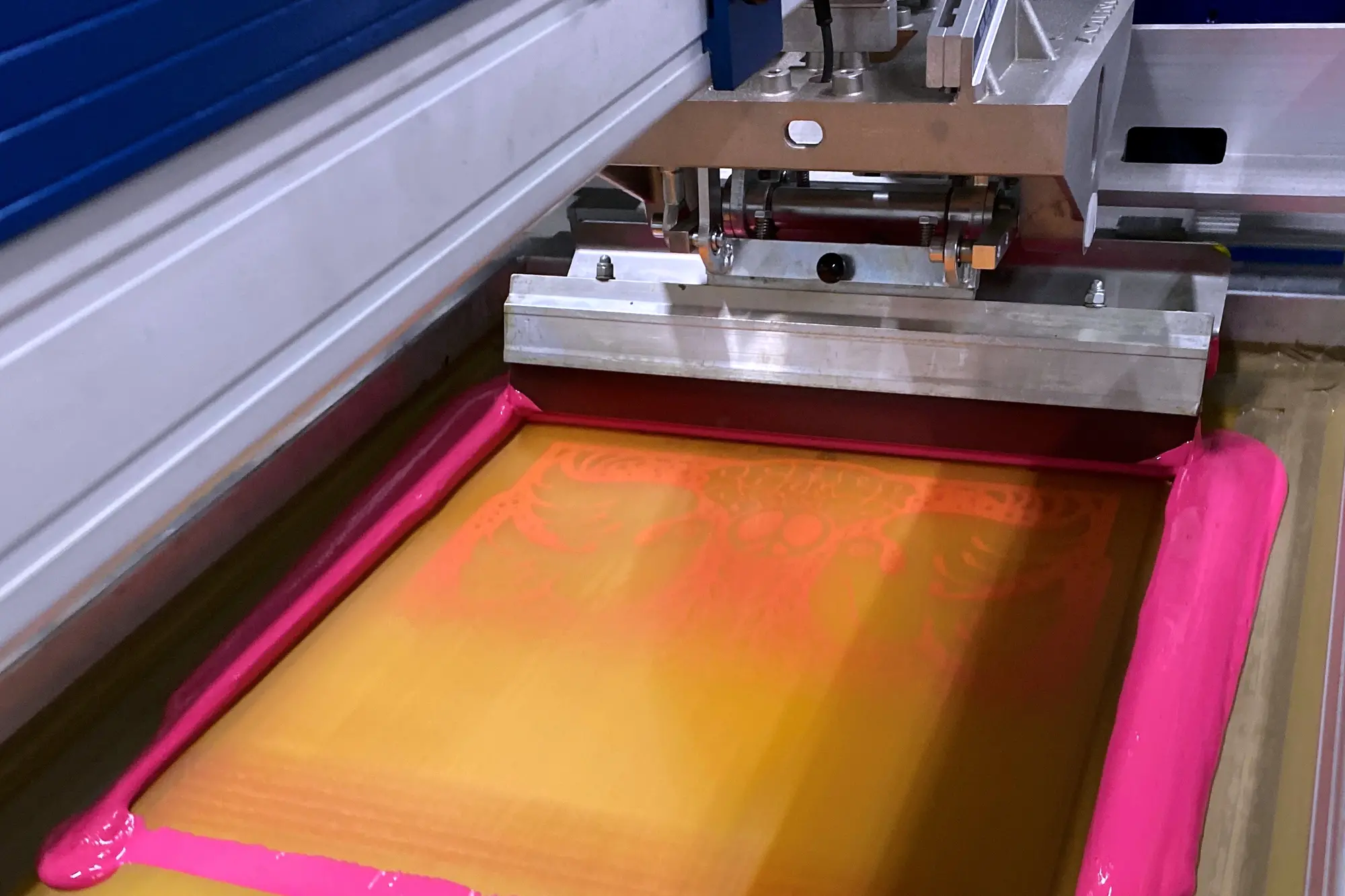

Bespoke artwork is accurately screen printed onto the bag using OKEO-TEX approved water-based inks.

The bag panels are then stitched together to create the bag, which can be of any size or shape as required.

After a rigorous quality control procedure, the finished bags are then sent to the customer.